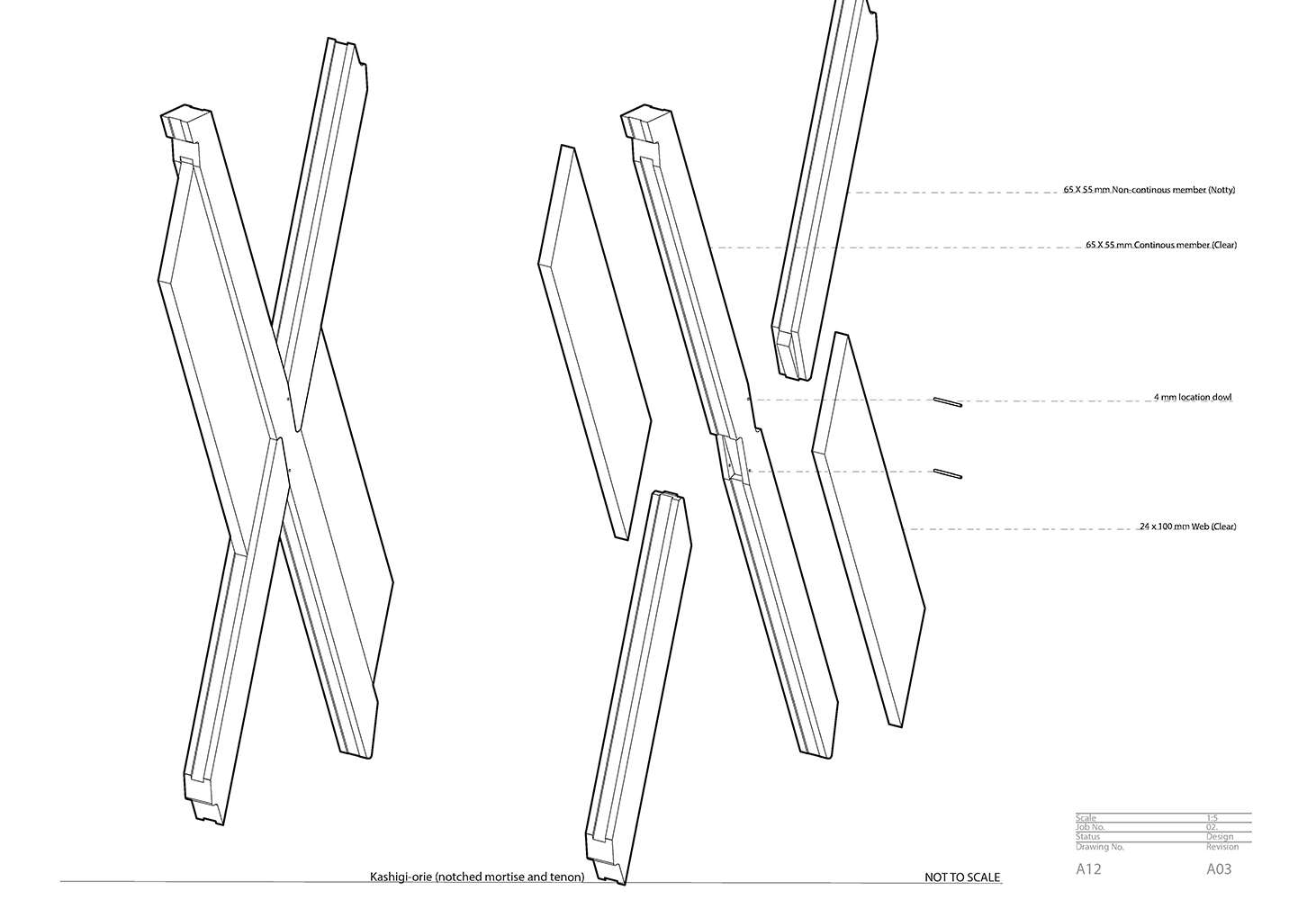

The role of carpenter in traditional Japanese architecture is as much an architect as a craftsman. Japanese joinery created by miyadaiku carpenters (carpentry techniques using interlocking wood without nails) allows timber connections to be resolved by sophisticated joints without relying on mechanical fastenings. This approach to timber design has been largely lost with the adoption of mechanical fastenings such as nail or screw connections, especially in the construction of structures with many small timber members. Largely, this is the result of the expensive labour cost associated with making timber joinery, leaving this craft to be the reserve of high-end furniture; no longer being seen in the realm of 21st-century building.

Sophisticated timber joints are still used in structures with large timber members which cost thousands of dollars. Using CNC milling to cut the joints accurately; with timber of this scale, the time and set up of the CNC milling is justified by the cost of the member being cut. However, a gap in the application of this technology exists regarding small members of timber, costing a fraction of what larger members do. Therefore, the cost to set up the CNC milling cannot be justified, and screws are used.